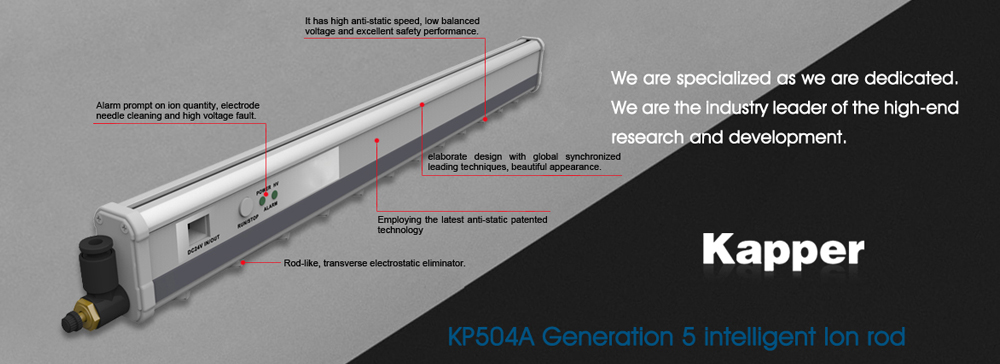

Main role is in addition to electrostatic ion fan, in addition to the static performance of our outstanding, prevent the pollution and destruction. Is electronic production line, machine maintenance personal type electrostatic protective area such as the ideal equipment. Refrigerator bladder is ABS material, the material will produce very high electrostatic after stamping, and in the production of refrigerator environment have mostly been common environment, this can result in plastic material surface adsorption amounts of dust in the air, but also very stubborn, whether you use something to clean, dust will adsorption or go up in a moment. We can choose two methods to solve this problem, one is to control the amount of dust and build a clean room, but it's hard to do, the project is too large, cost will be high); 2 it is to eliminate static electricity, the plastic surface after static elimination, can avoid dust adsorption. Because the whole production process is pipelining, and location, each process can have a static electricity due to repeated friction, handling, so every workstation in ion fan, in order to match the needs of the dust removal, advice can be combined with dust removal of electrostatic eliminator used together.

Previous:Already the first article

Next:The ionization static eliminator general specification expert validation will take place in suzhou